Which Material is Used in Soldering Iron Tips?

Which Material is Used in Soldering Iron Tips?

Soldering iron tips are typically made of copper, iron, or nickel-plated copper. Each material has pros and cons; the choice depends on the application.

Which Material Is Used in Soldering Iron Tips? All You Need to Know

Soldering Iron

A soldering iron is a hand-held tool to melt and flow solder into a joint between two or more metal pieces. The soldering iron has a handle and a tip made of hot metal. The information is generally made of copper, a good heat conductor. It has a layer of solder on it. The handle is protected so that it won’t get too hot.

Soldering irons are essential tools for putting together and fixing computer parts. They heat up and melt solder, which is then used to connect different computer parts. The solder bond depends on the soldering iron tip and the material used at the end.

Which Material is Used in Soldering Iron Tips?

Most soldering iron tips are copper, iron, or copper coated with nickel. Each material has pros and cons. Therefore, it depends on use and user preference.

Copper

Copper is often used for the tips of soldering irons because it heats up quickly and evenly and has good thermal conductivity. Copper tips also tend to last longer and won’t rust. But copper tips can’t be used with lead-free solder, which needs to be heated to a higher temperature and can cause the copper to wear away faster. Acidic fluxes are also unsuitable for copper tips because they can eat away at the copper and make it rust.

Iron

Iron is also a common material for the tips of soldering irons, especially when using lead-free solder. Copper tips melt at a lower temperature than iron tips, so iron tips can be used with solders that melt at a higher temperature. Iron tips are less likely to erode when using lead-free solder and are more rust-resistant than copper tips when used with acidic fluxes. But iron tips heat up more slowly and evenly than copper tips, which makes it harder to solder.

Copper Tips with Nickel Plating

Copper tips with nickel plating are a mix of copper and iron tips, so they have the best qualities. When used with lead-free solder or acidic fluxes, these tips last longer than copper tips because the nickel plating protects against rust and wear. Because the copper core is good at transferring heat, these tips heat up quickly and evenly. But nickel-plated copper tips cost more than copper or iron tips, making them harder for artists and do-it-yourselfers to get.

Reasons to Protect Soldering Iron Tips

Copper, iron, or nickel-plated copper protects for these reasons:

- Copper, iron, and copper with nickel are all good at transferring heat. They can quickly and evenly move the heat from the soldering iron to the work piece. It is essential because it helps ensure the solder melts appropriately and the joint is correctly assembled.

- Copper, iron, and copper that has nickel on it are all vital things. It means that they can handle the high heat and wear and tear that soldering iron tips go through. It helps ensure the tips last long and don’t have to be changed often.

- Copper, iron, and copper that have nickel on it are all corrosion-resistant. It means they can handle the complex conditions. It keeps the ends from rusting or corroding, hurting them and making them less valuable.

Overall, copper, iron, and copper coated with nickel are good ways to protect the tips of soldering irons. The best material for a job relies on what it needs to do.

Things to Consider When Picking a Soldering Iron Tip

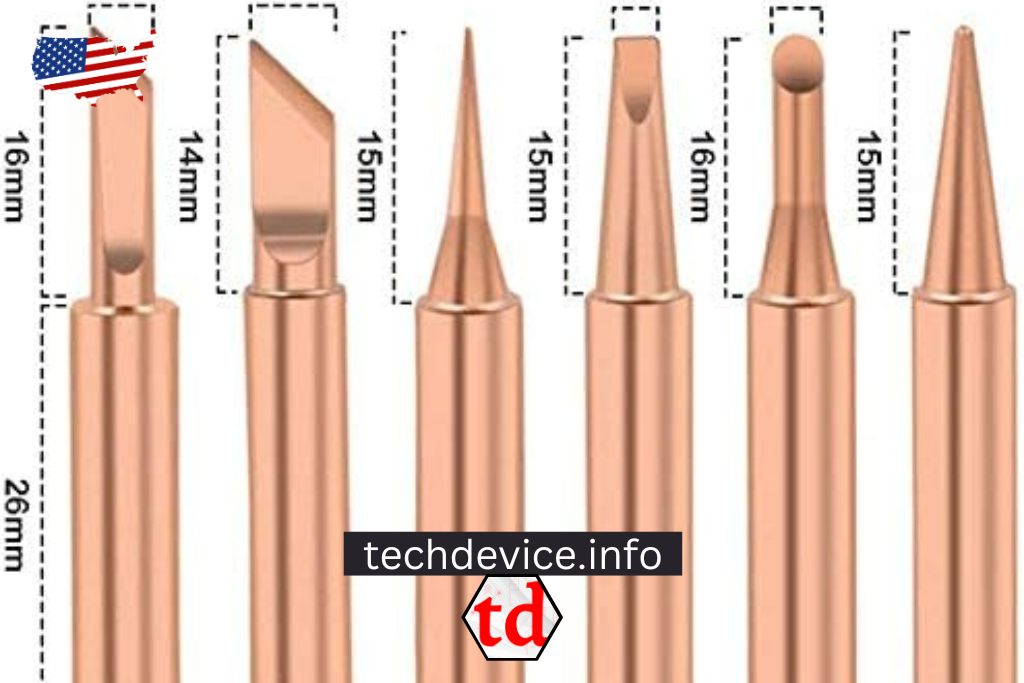

- The shape and size of the tip can also affect how well it works, along with the material it is made of. It comes in different forms, like a knife, a cone, or a point. Each shape is suitable for a different kind of soldering job. For example, a chisel tip is best for soldering extensive areas, while a pointed tip is better for precise work. The size of the information also affects how well it works. More effective tips are better for bigger soldering jobs, while smaller tips are better for smaller, more delicate ones.

- The coating on the tip is another thing to consider when picking a soldering iron tip. Some suggestions are covered with iron or nickel to protect them from corrosion and erosion. In contrast, others are covered with a tin layer, making it easier for the solder to move. Tinned tips are constructive for starting because they make creating clean, smooth solder joints easier.

Consider how the soldering iron will be used and the user’s preferences when choosing a tip. For most soldering jobs, a simple copper tip may be enough for artists and do-it-yourselfers. An iron or nickel-plated copper tip may be better for more advanced electrical work or use with lead-free solder or acidic fluxes.

Advantages and Disadvantages

Copper, iron, and nickel-plated copper tips have advantages and disadvantages:

Copper

Pros

- Copper is a suitable heat carrier for tips because it helps spread the heat evenly. It’s necessary for a good solder joint.

- Copper is a cost-effective material.

- Copper is easy to sell, so it’s a good choice for people just starting.

Cons

- It doesn’t last as long as other products.

- Copper is weaker than iron or nickel-coated copper. It means copper tips are more likely to break if they fall or are handled roughly.

- Copper is a metal that can rust if it isn’t taken care of properly. It can be a problem if the soldering iron is used in a place that is too wet or has many chemicals.

Iron

Pros

- Iron is more vital than copper, so iron tips are less likely to break if they fall or are mishandled.

- Iron is less likely to corrupt than copper, so iron tips are less likely to break if used in a humid or corrosive climate.

- Copper can’t take as high temperatures as iron can, so iron tips can be used for more difficult soldering jobs.

Cons

- It doesn’t transfer heat as well as copper. Iron welding tips take longer to heat up because copper conducts heat better.

- Most of the time, iron soldering tips cost more than copper ones.

Copper Covered in Nickel

Pros

- Nickel-plated copper distributes heat evenly, making it ideal for soldering iron tips. It is vital to do if you want to make a good solder joint.

- The copper coated with nickel is a strong material that doesn’t rust and doesn’t wear down quickly. It means copper tips coated with nickel will last longer than copper or iron tips.

- Nickel-plated copper doesn’t rust or corrode, even if it’s used in a humid or corrosive climate.

Cons

- Most of the time, nickel-plated copper soldering tips cost more than copper or iron soldering tips.

Ultimately, the best material for the tip of a soldering iron depends on what it will be used for. For example, if you’re welding small electronic parts together, you’ll need a tip that can transfer heat well and lasts for a long time. If you are welding more extensive parts, you can get away with a cheaper end.

Conclusion

In conclusion, the material used in soldering iron tips is a big part of how well and long they work. The most common materials are copper, iron, and nickel-plated copper. Each has its pros and cons. When picking a tip, you should also consider how well it will work based on its size, shape, and coating. By selecting the right direction and keeping it in good condition, users can ensure that their electronic projects work well and have clean, strong solder joints.