How to Fix the Soldering Iron Tip – All to Know

How to Fix the Soldering Iron Tip – All to Know

Curious to fix the soldering iron tip? Here, we will help you with simple steps to avoid damaged and oxidized soldering iron tips.

How to Fix the Soldering Iron Tip?

Over time, rust, fire, or hitting something can damage the tips of soldering irons. If the tip of your soldering iron has cracked, you are probably thinking about how to fix the soldering iron tip. In this guide, I’ll explain how to fix the tip of a soldering iron in a few easy steps.

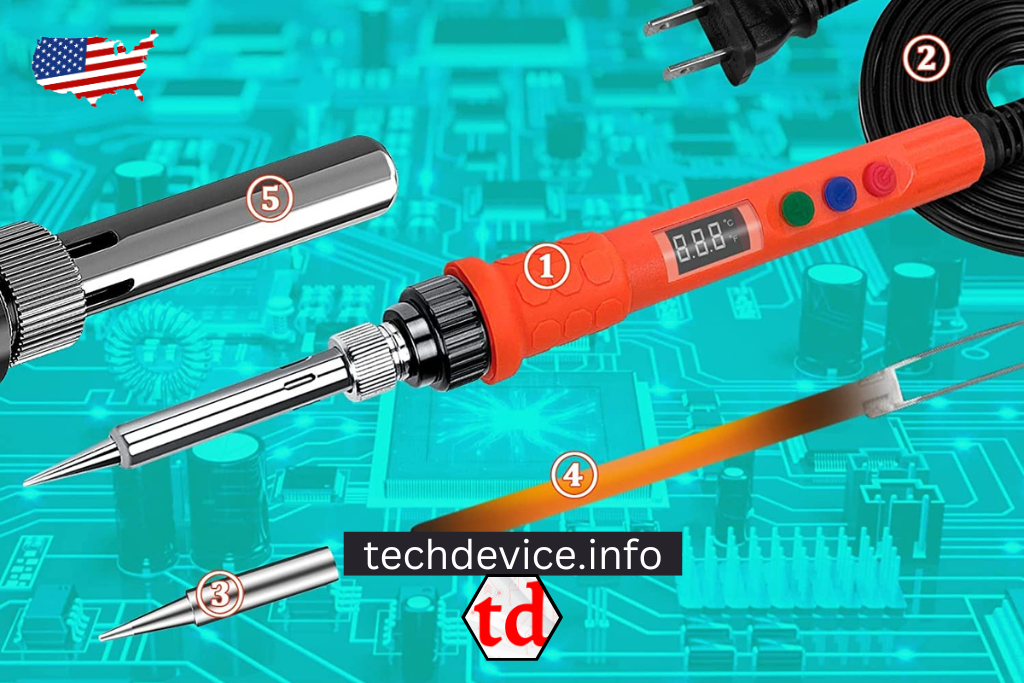

Materials

- Soldering iron

- Wire brush for brass

- Isopropyl alcohol

- Solder

What Is the Soldering Iron Tip?

The part of the soldering iron that touches the soldered item is called the tip. Copper or iron, which can handle high heat, are used to make it. The shape of the tip makes it possible for the solder to run easily and evenly.

There are many different kinds of soldering iron tips, each with a different job. There are tips for general soldering, precise soldering, and joining small parts, for example. Consider the soldering you will perform, the size, and the heat required when choosing a soldering iron tip. Here are a few examples of popular soldering iron tips:

Conical

Most people use this type of soldering iron tip. It can solder many things.

Chisel

This tip aims for precise soldering. It has a flat end that looks like a chisel. It makes it easier to control when gluing small parts.

Round

This soldering tip aims for large items. It has a flat end that is round and spreads heat evenly.

This tip on the needle aims for soldering very small parts. It has a long, thin end that makes it easy to get to places.

Needle

You can clean the tip of a soldering iron with a metal wire brush or an isopropyl alcohol-soaked sponge. Make sure to clean the tip before and after every use. It will keep it clean and ensure it heats up evenly.

How to Use Soldering Iron?

Here are some tips for using soldering iron:

- When welding, you should always wear safety glasses.

- Before each use, tin the tip of the soldering iron. It will make a layer of solder on the tip, which will help keep it from rusting.

- Heat the thing you want to join, not the solder. When the hot thing comes in touch with the solder, it will melt.

- Don’t let the soldering iron get too hot.

- Remove the soldering iron from the item as soon as the solder has melted. If you hold the iron in place for too long, it could hurt the thing.

- Clean the tip of the soldering iron after using it.

Soldering kits need to include soldering iron tips. You can ensure your soldering projects work by picking the right tip for the job and using it correctly.

Why do Tip Cracks happen?

Change in temperature

Most lead-free soldering methods require high working temperatures, which heats the tip. When you wipe the hot tip with a wet cleaning brush, you create a shock that can cause the plating layer to crack.

Use and abuse

Soldering tips can wear out faster if you don’t know how to use them right. Even workers doing their jobs for a long time can wear out. When the plating layer goes away, the copper core is exposed, which leads to corrosion.

Corrosion

Soldering tips corrode when exposed to air, too much heat, flux residues, and other things in the outside world. When operators use flux, the tip is likely to wear down quickly.

Effects of de-wetting

It is the most general tip wear or repair symptom. The following things cause de-wetting:

- Too much cleaning of the tip

- During lead-free treatments, you can clean the tip with a damp sponge.

- The bad time to wipe off the tip

How to Fix the Soldering Iron Tip from Cracking?

Pick the right hint for the job.

Fine tips are good for soldering delicate areas but not for tough jobs. A broad tip can use for any task. Experts say that you should use chisel-shaped tips instead of cone-shaped ones. Also, use liquid flux and the GW tips when bonding to Gull Wing or J-Led parts.

Use the right iron tip for soldering.

Use the right support for the iron and check it to ensure the tube is not worn or broken. If you don’t do this, the iron may hit the funnel spring if you don’t do it.

Make sure to tin the tip.

Tinting cuts down on rust and makes more surface area for heat to move over. It also means you don’t have to press the tip down hard.

How to Fix the Soldering Iron Tip?

If the tip of your soldering iron isn’t working right, it could be rust, overheating, or damage from being dropped or hit. Here are some suggestions for fixing the tip of a soldering iron:

Get rid of rust

Eroded tips heat poorly and are black or brown. Use a metal wire brush or a sponge dipped in isopropyl alcohol to remove oxidation. Make sure to clean the end well.

Smooth the tip

Once the rust is gone, the tip needs to be tinned. It will make a layer of solder on the tip that will help keep it from burning again. To tin, the tip put a small amount of solder on it and heat it until it melts and flows equally.

Overheating

If the tip is getting too hot, it could be because you are using a soldering iron that is too strong for the job, you have left the soldering iron in one place for too long, or you haven’t cleaned the tip well enough. Ensure you use the right soldering iron for the job, don’t leave it in one place for too long, and clean the tip often to keep it from getting too hot.

Body damage

Damage to the body. For example, if the tip is bent or chipped, it may need to be changed. You can get replacement tips at most hardware shops and online.

Here are some more suggestions for repairing the soldering iron tip.

- clean the tip before and after use,

- Put the soldering iron somewhere cool and dry.

- Don’t leave the soldering iron plugged in when you’re not using the soldering iron.

- If the tip break, you should replace it.

Using these tips, you can keep the tip of your soldering iron in good shape, which has worked well for many years.

Fixing A Soldering Iron Tip Has Both Pros and Cons

Pros

- It is easy to fix and doesn’t cost much.

- Saving money comes from not having to pay someone else to do it.

- It can make your soldering iron last longer.

Cons

- If you aren’t careful, you can do more damage to the tip.

- If the tip breaks badly, fixing it might not be possible.

If the soldering iron is old or inexpensive, the time and effort may not be profitable.

Conclusion

It is a simple way to fix a soldering iron tip for a long time. Doing it, you can clean and tin the tip of your soldering iron to get it working again.

Here are some tips to keep the soldering iron in good shape:

- Clean the tip before and after using it.

- Put the soldering iron somewhere cool and dry.

- Don’t leave the soldering iron plugged in when you’re not using the soldering iron.

Using these tips, you can keep the tip of your soldering iron in good shape, which has worked well for many years.